Keep Your Conveyor and Sortation Systems Running Efficiently by Leveraging the Data Available from Sensors

Today’s conveyor and sortation systems are increasingly able to communicate with your software before equipment failure occurs.

Odds are, you drive a car with a sophisticated electronics system. A light might pop up on your dashboard to tell you your tire pressure is low, for example. Or when it’s time for routine maintenance—oil changes and the like—you’ll get another notification. All of these electronic systems work together to keep your car running well and out of the shop for repairs.

In material handling, the equipment on your floor is also becoming more sophisticated, and now often has its own dashboard. This is the case with many new generation conveyor and sortation systems. The advantage is that by using equipment equipped with sensors, you can avoid downtime and losses while increasing your productivity and efficiency.

The newer conveyor and sortation systems are equipped with sensors that give you all the data and information you need to signal when a system might fail. By accessing this information on your system’s dashboard, you can stay ahead of any downtime. While your maintenance staff is likely well trained and doing their jobs well, you can prevent downtime much more effectively with detailed, real-time feedback.

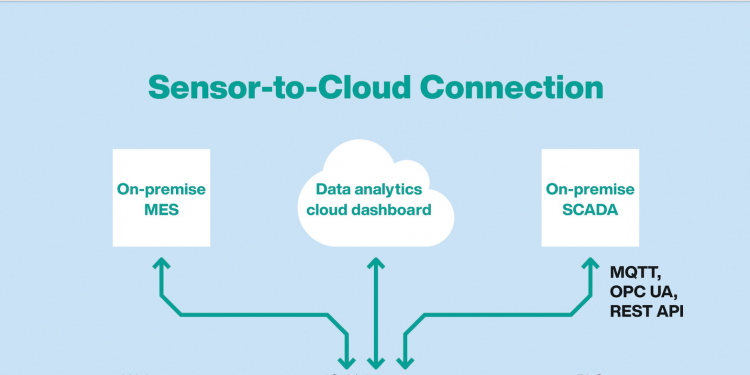

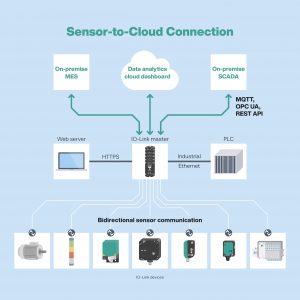

A conveyor and sortation system dashboard can retrieve many details from its sensors and send them to your own software systems, such as WMS or WCS, via the cloud. This can include data on how many hours the machine has been running, for example. Or there may be sensors that measure vibrations, providing information about how many cycles the equipment has gone through. With this information in hand, you can monitor system performance more effectively and plan maintenance work rather than facing an unexpected shutdown.

If you have purchased a new conveyor and sortation system in recent years—or plan to purchase one soon—chances are it’s equipped with this sophisticated data capture and reporting. If you want to retrofit, however, that’s possible, too. In either case, the sensors record the condition of the motors and other critical parts and provide you with the details you need to avoid breakdowns.

The newer equipment with sensors is naturally more expensive than its predecessors, which is probably no surprise. Although some operations may shy away due to initial costs, that’s a mistake. In the long run, investing in equipment that works will pay for itself sooner than you might expect. You will save money by maintaining your operations and delivering your packages on time, as well as on labor costs. With today’s tight labor market, companies cannot afford to let their employees sit idle. Every minute inactive means less productivity and lost revenue.

Given the obvious benefits of implementing conveyor and sortation systems with intelligent sensors and dashboards, we can expect adoption rates to continue to go up. If you haven’t yet looked into the possibilities, it’s worth taking a look.

To learn more about MHI’s Conveyor and Sortation Solutions Industry Group: www.mhi.org/conv

For more articles and podcasts about Conveyors and Sortation:

Purchasing Conveyors With Sustainability In Mind

Using Conveyors for Loading and Unloading Trucks & Containers

Podcast: CSS – HOW TO AUTOMATE FOR THOSE WHO HAVEN’T AUTOMATED

Reconfigurable Conveyors For The Win

The Importance Of Digitization In Material Handling

Why You Should Consider Decentralized Networks