Adding Robots to the Cold Chain

With the right application, robots can play a key role in your cold-chain operations. Robotics in manufacturing and warehousing are seemingly everywhere these days, but can they also work in refrigerated environments? Yes, and the similarities to ambient environments probably ...

Podcast: Robotics and Humans: A Synergistic Workforce

The latest episode of the MHI Industry Leadership Podcast, hosted by Christian Dow and co-host Frank Schwartz, dives into a topic at the forefront of modern logistics and warehouse management: the integration of robotic automation in work environments traditionally dominated ...

Reimagining Warehouse Boundaries with Robots

The name of the game in warehousing is increasing productivity. There are many ways to go about that, but most often, technology is the key piece of the equation. Robots are increasingly the tool of choice, for many reasons. When ...

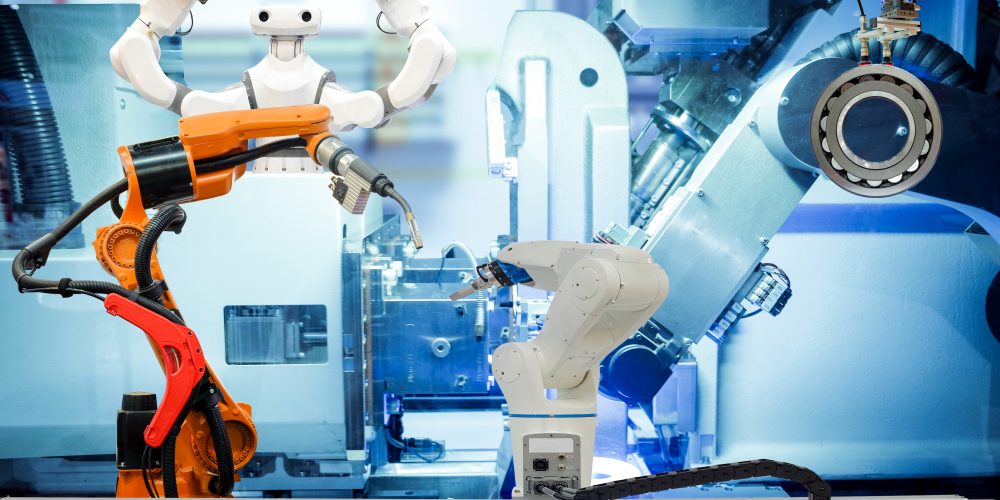

Robotics 101

Learn how different robots can operate within your facility to enhance productivity. Robotics are taking on an increasingly larger role in the warehousing environment, but that hasn’t always been the case. Traditional fixed robots–long a fixture in the automotive industry—haven’t ...

Robotics in the Warehouse

The collaborative role of robots and humans leads to big results. The term “robots” gets thrown around loosely, especially in the context of material handling. While it represents a very broad category of equipment, it can be helpful to understand ...

Order Orchestration Optimization Through Robots

Today’s robots are more sophisticated than ever, as is the software that coordinates them. Orchestrating work flows to ensure efficient order processing is a complex job, even more so when completing interdependent tasks manually. Human capital affords vulnerability with potential ...

Working in Harmony

Robots and humans together make for a more productive warehouse. Even prior to the pandemic, warehouses struggled to find enough skilled labor to fill all their positions. Once the pandemic kicked in, that number exploded—in just two years, businesses added ...

Robotics in Logistics, Part 2 – You’ve Decided to Add ...

As robots become more common on warehousing and manufacturing floors, more companies are intrigued by the benefits they might offer their operations. If you’ve been investigating robots and have determined their addition is justified in your operations, you are ready ...

Robots in Logistics Pt. 1

Talk of robotics in logistics is everywhere, and for good reason—they can deliver significant value. Autonomous mobile robots (AMRs), automated storage and retrieval systems (ASRS), industrial robots, and automated guided vehicles (AGVs) all can take on significant workload, especially those ...

Will Robots Change Your Warehouse Culture?

Long before robots began joining workers on the warehousing floor, there was fear that machines would someday replace humans. While that scenario is proving untrue, many employees express skepticism and concern when autonomous mobile robots (AMR) or articulated arms first ...