Virtual Visualization, Simulation & Analysis: A Critical Component of Automating Your Warehouse

Digitalization is driven by eco-conscious yet hyper-connected consumers. These new-age consumers want novel experiences and innovative products that meet their needs. Additionally, they want their products delivered safely and as quickly as possible.

To satisfy ever-growing consumer demands, enterprises should do more with less. That means they should deliver more products and services using fewer workspaces and a smaller workforce.

Automation is the key to achieving this. With technologies like Automated Storage and Retrieval Systems (ASRS) and Robotics as a Service (RaaS), businesses can automate several warehouse functions and gain better efficiencies.

Since these systems don’t get tired or take breaks, they help keep your business productivity high with fewer resources and a smaller workspace. Higher productivity is essential to meet the increased demand from e-commerce channels. Automated warehouses are the key to keeping up with this rapid pace of higher productivity and demand.

However, virtual visualization, simulation, and analysis play a critical role in a successfully functional automated warehouse.

Virtual visualization

Virtual visualization

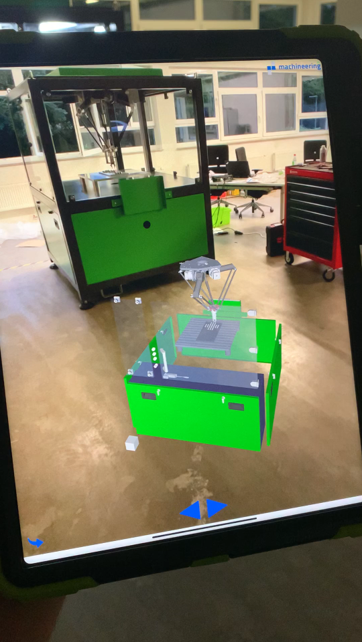

A picture is worth a thousand words. The virtual visualization capability makes it possible to get a bird’s-eye view of your warehouse activities. For example, inventory movement and employee performance. It also allows for identifying the location of the inventory and determining its ideal location. In addition, with 3D scanned data, it is now possible to review any existing warehouse facility and then develop a 3D model to visualize and optimize the layout virtually.

Simulation

The simulation uses a computer model to help analyze and test the warehouse facility in a virtual setting. This process cuts the time, risks, and costs of physical testing. The simulation model can introduce and adjust the storage space, racks, conveyors, Automated Guided Vehicles (AGVs), and even the personnel. With the help of this virtual simulation, warehouses can determine how to fully utilize their resources and maximize efficiency without disrupting their existing facility.

Analysis

One of the important benefits of digitalizing the warehouse is the capability to analyze the interacting parts and validate the system performance of automated warehouses. This is possible through Digital Twin simulations and Internet of Things (IoT) capabilities. Digital Twins are computer-based models that accurately represent real-world physical models. They map critical process stages, including functional modeling, mechanical modeling, and system simulation.

The performance metrics available through Digital Twin models provide valuable insights into how the facility is performing and help decision-makers take proactive measures to prevent breakdowns. These digital models also help quickly test new solutions before implementing them physically, saving businesses from spending more on physical testing.

Warehouse automation for new-age businesses

Warehouse automation also fits the bill in a few other ways. It has the potential to attract younger millennials and Gen Z workers who grew up holding mobile phones in their hands. For the younger ‘smart device’ generation, it is natural for them to use cutting-edge technology rather than working in an old-school warehouse ecosystem. Automation tools like ASRS and RaaS can help keep the younger workforce more engaged.

Many companies worry about the hefty cost of warehouse automation. However, they need to realize that this cost is a one-time investment. One that can reduce or eliminate many ongoing costs like workforce training, salaries, healthcare, and more. It can also deliver a quicker and better Return on Investment (ROI).

For more articles and podcasts about Conveyors and Sortation:

Why You Should Consider Decentralized Networks

Podcast: CSS – HOW TO AUTOMATE FOR THOSE WHO HAVEN’T …

Electrical Motor Standard Differences

From Preventative To Predictive Maintenance Of Automation

Large Parcel Shipping Is Growing

5 Ways Robotics Improves Conveyor And Sortation Induction

For more information about the Conveyor and Sortation Solutions Industry Group, click here.