Maintenance Check: From Reactive to Predictive

Modern tools are changing the way you maintain your equipment—with big savings to be had. The normal, long-standing tradition with material handling equipment is to react when something fails. Your conveyor grinds to a halt and you bring in your ...

Creating End to End Solutions

The future of maintenance is looking prescriptive. It hasn’t been all that long since the typical approach to maintaining equipment involved a pen and paper. Maintenance staff would make the rounds, looking at equipment for any issues that might lead ...

Cloud Vs. On-Prem WCS

Considering the pros and cons of each for an optimal solution. Many warehouses these days are full of automation, and for good reason. By placing automated equipment and systems on your floor, you’re better able to respond to market conditions. ...

Digitization of Intralogistics—Replenishment

Providing traceability and visibility can drastically reduce lost inventory. As the pandemic laid bare, replenishment is one of the trickiest parts of the supply chain. Supply and demand has proven to be volatile these days, and companies must work extra ...

Digitization of Intralogistics: Labor

Managing information rather than products is a good way to attract and retain labor—key in today’s environment. One of the most critical topics in today’s warehousing and manufacturing is digitization of intralogistics. It represents the flow of both materials and ...

Cloud Vs On-Prem WES

The pros and cons of keeping your WES local A warehouse execution system (WES) is one of a suite of warehouse automation software that you can choose to direct your daily operations. Sitting between the WMS, which is responsible for ...

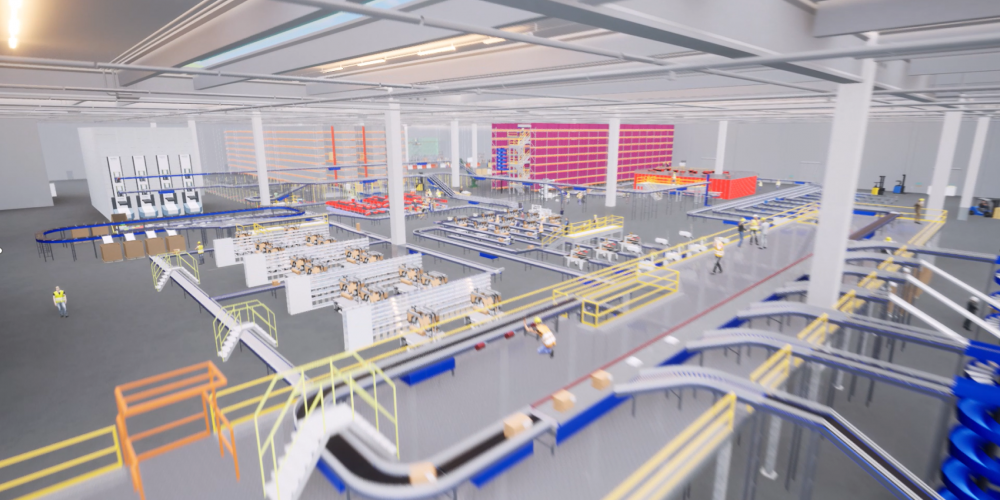

Digital Twin for Intralogistics

A new MHI white paper explains how you can use a digital twin with intralogistics. Today’s logistics are smart logistics—not just the transfer of products, but the transfer of information, as well. The common term for this modern system of ...

The Digitization of Intralogistics: Returns

Returns have come a long way in the past few decades; technology is helping. Returns are a big deal in logistics, and since the pandemic-driven surge in ecommerce, they are also more common than ever before. The National Retail Federation ...

Past vs. Future: The Difference Between On-Premise and Cloud-Based WMS

Warehouse management systems (WMS) have been a nearly essential part of efficient warehousing operations for several decades now. Serving as the brains of an operation, WMS systems orchestrate all processes, from receiving to put away and picking to shipping. They ...

Sophisticated Condition Monitoring

When you move away from traditional scheduled maintenance and let computers do the talking, you can prevent major equipment breakdowns. For any manufacturing or warehousing operation, the biggest nightmare scenario is the breakdown of a major piece of equipment, one ...