Digitization of Intralogistics: Software

There are multiple types of software solutions designed to optimize your warehouse. Here’s what each can and can’t do:

If you take a scan of your facility, you’ll spot storage racks, conveyors, lift trucks, and maybe even mobile robots. They all operate individually, but to truly optimize, they should be orchestrated by intelligent software. That’s the missing piece in your puzzle, the one that gives you real-time visibility, scalability, and flexibility. Digitizing your operations is the path to operational efficiency, no matter what combination of material handling you have in place.

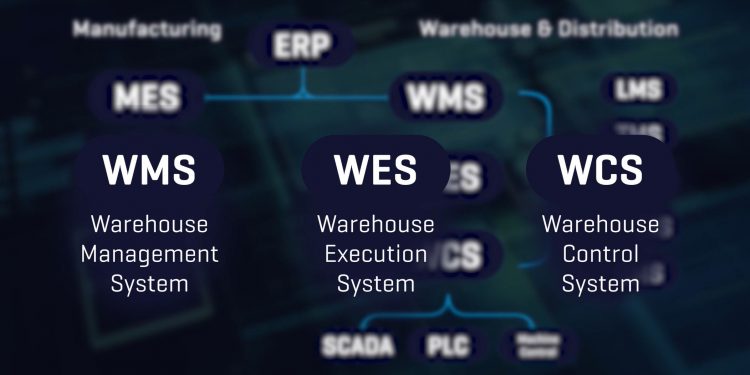

The odds favor you already have some sort of software in place, perhaps an enterprise resource planning (ERP) system. While a key element of overall business success, ERP isn’t the best option for digitizing your warehouse. They lack the ability to manage the complexity involved in today’s operations, which can lead to slowdowns in your business. Or, if you’re focused on manufacturing, you may use an MES to bridge the gap between the planning and execution phases.

For warehousing, the answer lies in other types of software. The potential solutions include warehouse management systems (WMS), warehouse execution systems (WES) and warehouse control systems (WCS). Each has its own purpose and function, and also the ability to work in harmony with the others.

You might consider a WMS as the heart of a warehouse. It can optimize your operations, increase capacity and provide you with real-time visibility. It also shines a spotlight on control and automation, allowing for seamless, connected operations. With WMS, you can efficiently manage your inventory, allocate labor to the needed spots, and increase your fulfillment speed by automating order picking and reducing errors.

A WES is designed to specifically orchestrate labor and equipment. Through real-time visibility, a WES prioritizes tasks, cutting wait times and promoting efficient use of resources. It’s critical if you want to improve your operations and productivity.

Finally, a WCS has the ability to communicate with automated material handling equipment. These systems assist in efficient product flow across all your material handling equipment and their related systems. Think of a band leader to your conveyors, carousels, ASRS, pick-to-light systems and mobile robots. Together, and these three systems can effectively elevate your game and offer you a competitive advantage.

If you’re looking to take your software systems to the highest level, you can also integrate them with systems like labor management systems (LMS), transportation management systems (TMS), CMMS, which is computerized maintenance systems, and order management systems (OMS).

While there are many types of software with multiple purposes, figuring out which are ideal for your particular operations requires the assistance of a software provider and/or a consultant or integrator. Together, you can map out your operations, identify your areas of need, and begin a plan to implement and optimize. With visibility and efficiency, your warehousing operations can transform from a traditional, manual environment to a next-generation of success.

The Solutions Community Software Committee recently released a video on “Unlocking Efficiency: A Warehouse Automation Software Overview.” For additional information on software solutions, the video can be viewed through MHI View.

For more information about the Solutions Community: mhi.org/solutions-community

For further articles from the Solutions Community:

Forward Pick Area—Design and Operations

Maintenance Check: From Reactive to Predictive

Digitization of Intralogistics—Replenishment

Digitization Of Intralogistics: Labor

Digital Twin for Intralogistics

The Digitization of Intralogistics: Returns

Past vs. Future: The Difference Between On-Premise and Cloud-Based WMS