How Parcel Handling Conveyors And Sortation Solutions Can Mitigate The ...

Consumer spending during 2021’s holiday season — between November and December — is forecast to grow anywhere from 8.5% to 10.5% over 2020, says the National Retail Federation (NRF). In dollars, that’s a range of $843.4 billion to $859 billion. ...

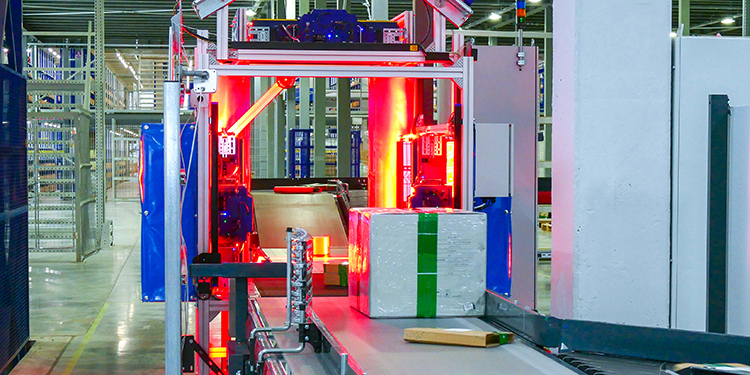

Safety And Speed: Latest Conveyor And Sorter Features Deliver Both

Two decades ago, high-speed conveyors and sortation equipment were running at 50 feet per minute. Today? Try nearly 700 feet per minute in certain applications. And while that high rate of speed translates into faster movement and sorting of the ...

Key Considerations In Determining Conveyor And Sorter Total Cost Of ...

While many operations commonly calculate return on investment (ROI) when making a significant capital expenditure on new material handling equipment — such as conveyor or sortation systems — more are beginning to also consider the total cost of ownership (TCO) ...

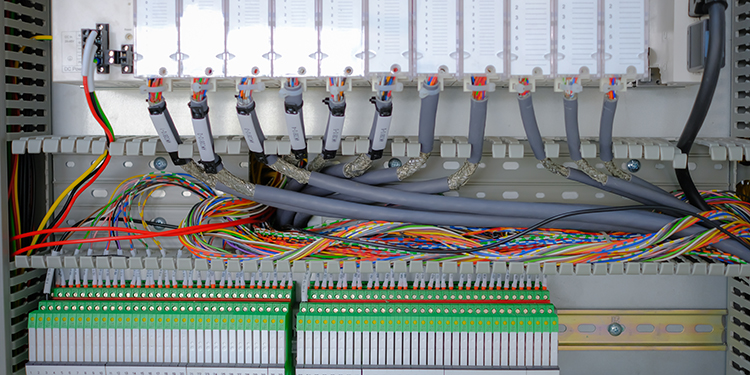

Conveyor And Sortation Controls: Things To Consider When Choosing Between ...

In a previous post, the meanings of centralized and decentralized control for conveyors and sortation systems were defined. Deciding between decentralized or centralized controls for a conveyor or sortation system doesn’t have to be difficult. It does, however, require a ...

Conveyor And Sortation Controls: Defining Decentralized And Centralized Architectures

The operation and function of conveyors and sortation systems are driven by one of two types of control: centralized or decentralized. What do each of those terms mean? As it turns out, the material handling and controls industries often use ...

Key Areas, Considerations For Integrating Robotics And Automation With Conveyor ...

While high competition for scarce warehouse and distribution labor — and the subsequent rise in wages — had already prompted more operations to investigate robotic and automation solutions to augment their current workforce, COVID-19 compelled many companies to adopt those ...

Key Considerations When Transitioning From Bulk To Singulated Parcel Flow

With the exponential growth in e-commerce and direct-to-consumer parcel shipments, more carriers’ shipping and handling facilities are assessing a change in their current conveyance and sortation equipment and processes. Making the shift from bulk parcel flow (an unorganized mix of ...

CSS To Host ProMatDX 2021 Education Session Focused On Virtual ...

Since nobody has yet created a reliable crystal ball for predicting the future, the members of the Conveyor & Sortation Systems (CSS) industry group of MHI will share insights into a viable option — virtual simulation software — during a ...

Tips For A Smooth Conveyor And Sorter Design And Installation ...

Congratulations — you’ve gotten your organization’s top brass to approve the purchase of a new conveyor or sortation system for your warehousing, distribution or fulfillment facility. Yet, with many companies justifying the investment based on a specific go-live date, keeping ...

Resource Shares Details On Vertical Reciprocating Conveyor Applications

Because they represent a small segment of the conveyor industry, vertical reciprocating conveyors (VRCs) are not universally known. That’s why the members of the VRC Subcommittee of the Conveyors and Sortation Systems (CSS) Industry Group of MHI have released a ...