How Parcel Handling Conveyors And Sortation Solutions Can Mitigate The Impact Of Labor Scarcity

Consumer spending during 2021’s holiday season — between November and December — is forecast to grow anywhere from 8.5% to 10.5% over 2020, says the National Retail Federation (NRF). In dollars, that’s a range of $843.4 billion to $859 billion. Included in those numbers are online and other non-store sales, which are also anticipated to rise between 11% and 15% over 2020 to a total of $218.3 billion to $226.2 billion. This, despite the current global supply chain woes that include backlogs of container ships at domestic ports that are delaying the delivery of items to retailer’s e-fulfillment warehouses and brick-and-mortar shelves.

That uptick in holiday buying can be attributed both to U.S. consumers’ current comfortable financial positions, as well as their pandemic-spurred increase in online shopping. In turn, the number of small parcels measuring 20 inches or less — specifically cardboard cartons, padded envelopes, and polybag mailers — is likewise expected to grow exponentially during the same timeframe. That means parcel handlers of all sizes, large to small, who still rely on manual labor to handle and sort all those shipments are likely to feel an intense strain on their internal resources due to the other ongoing trend: the labor shortage.

According to the Indeed Hiring Lab, job openings are vastly outpacing the number of available workers. Loading and stocking jobs were near the top of the list of most posted openings, according to the research arm of the job listings employment website. Those posts saw 96.8% growth over pre-Covid-19 postings from February 2020. With a lack of available workers, parcel handlers will likely struggle to keep up with the heightened holiday demands. That will certainly impact holiday deliveries, which will undoubtedly be delayed in many cases.

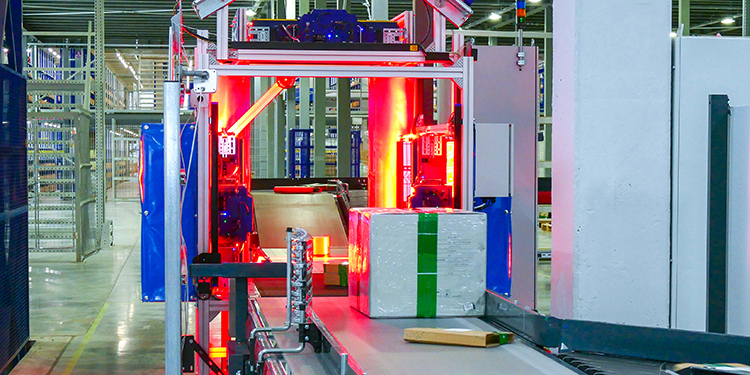

Not every parcel handler will feel the impact, however. Those that read the tea leaves after 2020’s holidays and anticipated increased growth in e-commerce and a challenging labor market were quick to make investments in supply chain technologies and solutions early in 2021. Specifically in automated equipment, such as conveyor and sortation systems, that help their existing workforce be even more productive and reduce the need for additional workers, either temporary or permanent. These automated solutions can help parcel handlers maintain high levels of accuracy while handling more packages at rates much faster than humans, ensuring that customer service level agreements (SLAs) for delivery timeframes are met.

As a general trend, parcel handling operations of all sizes have recognized the need to make investments in automated conveyors and sorters to boost their handling capacities while minimizing their reliance on scarce labor. The industry is responding with a range of parcel handling solutions and innovations that safely transport packages across a diverse range of speeds, from 50 feet per minute to 700 feet per minute. That breadth of varied solutions means mid-sized and smaller operations who previously were unable to justify a capital equipment investment in automated sortation or conveyors are now able to find right-sized solutions, whether they need to handle 2,000 or 20,000 packages per hour per system.

That said, material handling equipment manufacturers are likewise struggling with similar labor and supply chain woes. Organizations that signed contracts for automated sorters and conveyors at the outset of 2021 faced 12- to 14-week lead times; by the fourth quarter of the year, those lead times had grown to 30 to 40 weeks — and sometimes longer. This is due to a shortage of available skilled workers and material supply chain slowdowns, as well as the significant uptick in investment in these technologies.

However, as consumers’ expanded e-commerce shopping habits are expected to continue their growth trajectory, and labor availability unlikely to change anytime soon, companies that have not invested in these solutions will probably find it exceptionally difficult to remain competitive going forward. To ensure operational stability in the months and years ahead, it’s important to begin the process of moving toward automation now.

For those who wish to learn more about these varied automated parcel handling conveyor and sortation solutions and how they can help operations maintain accuracy, productivity, and high throughput in a challenging labor market, there are a variety of resources available from the Conveyor & Sortation Systems (CSS) industry group of MHI. The 30-plus members of CSS are the industry’s leading providers of conveyors and sortation systems. They have completed thousands of projects ranging from small, initial automation investments to large, complex projects synthesizing integrators, multiple vendors, and different municipalities. They design, fabricate, and install conveyor and sortation systems worldwide and in virtually every major manufacturing and distribution sector.

Additionally, a for those interested in seeing a broad range of automated conveyor and sortation solutions in person, including those designed for parcel distribution, multiple systems from a broad range of solution providers will be on display at MODEX 2022. Registration is free and includes access to both the exhibit show floor and more than 150 on-floor educational seminars. For more information, visit www.modexshow.com.