According to research conducted by Interact Analysis, the demand for collaborative robots — also known as cobots — that safely work alongside humans in manufacturing and distribution operations is expected to grow at an annual pace of more than 60% with a compound annual growth rate (CAGR) of more than 35% until 2027. This growth is being driven by the same force fueling more widespread adoption of all automated technologies: labor shortages. It can also be attributed to the increasing availability of these solutions at lower costs, making them more attractive to small- and medium-sized companies as well as major corporations.

In a recent MHI Solutions magazine article, “Productivity Increases When Robots Work Alongside People” produced by The Robotics Group, several opportunities for implementing collaborative robotics to handle a variety of tasks in warehousing and distribution centers are explored. Among them:

- For operations in geographic areas with very low unemployment and experiencing difficulty filling temporary roles during peak seasons, multiple robots — overseen by a single employee — can be deployed to autonomously scan and sort batch picks into discrete put wall cubbies for individual orders. This both increases throughput and accuracy while reducing labor requirements.

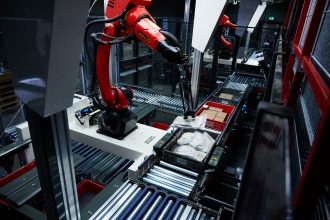

- By taking over repetitive tasks — such as folding boxes, applying labels and tape, picking items, unpacking boxes, filling containers, case packing, box palletizing, or packing orders — cobots free employees to handle assignments that require adaptive, problem solving skills, such as picking or packing fragile items, hard-to-handle items or complex orders. This also reduces repetitive motion injuries and fatigue, plus eliminates “boring” work for an increase in worker efficiency and satisfaction.

- Their inherent flexibility allows collaborative robots to be deployed in one application, then reprogrammed and moved to perform other tasks to support changing business processes and needs. Further, they are outfitted with sensors and their speed regulated to keep workers safe around them.

Additionally, the article explores an assessment process to help warehouse operators in determining whether collaborative robotics are right for their facilities and processes. Considerations include the number and diversity of item profiles — in terms of size and weight — that can (or cannot) be handled by the cobot; desired rate of consistent throughput over a given period of time; and matching the robot’s reliability and lifespan with the anticipated duration of the intended application.

For more information about implementing collaborative robots in warehouse and distribution center operations, read the full article here.