Your Guide to Successful Metrics for Automation Implementation

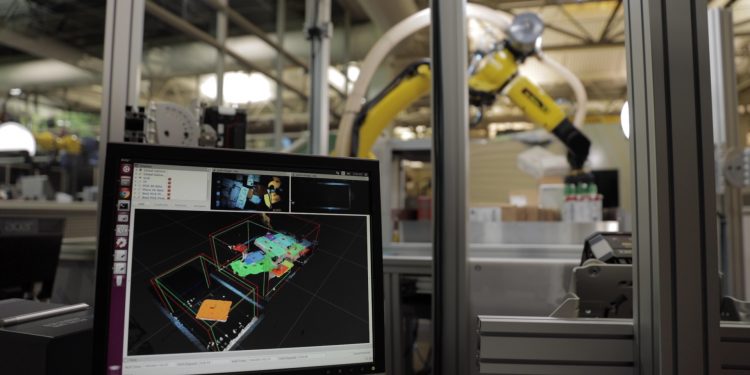

In a survey conducted in 2021, 20% of organizations globally considered adopting robotics for warehouse operations.

As this number grows, organizations need to figure out a way to ensure that their automation is working and measures the improvement in business performance. In addition, they also need to know what impact AI has had on their business in terms of meaningful figures that signify more than just speed and efficiency.

Quantifying metrics when implementing automation is crucial to track and verify progress towards a specific goal. While the Return on Investment (ROI) is a critical metric you should be keeping track of, there are several other metrics related to key aspects throughout the process, from the builds to deployment and testing.

This piece will help you better understand the relevance of each of these metrics and determine which ones you should be tracking.

How to create the proper success metrics

The two standard metrics you’ll need are throughput and labor savings. Along with them, you should also consider monitoring performance indicators, like productivity improvement and the cash flow of the business.

Throughput

Throughput is a crucial metric in Machine Learning that measures the performance of the various models for their specific applications. Throughput is measured in units of data processed per unit of time. So, for example, for data in the form of images, it would be image per second.

Labor Savings

Labor saving is a metric that helps you measure the impact of any implementation meant to reduce the cost involved in human labor. It could be the addition of a technology or solution that makes labor easier, eliminates repetitive tasks, or reduces hazards to the employee.

Return On Investment

ROI is the relationship of the monetary gain from an investment as a ratio to the cost of implementation. The key idea is that the returns should outweigh the amount invested in the given technology, which in this case would be automation.

However, the return can also be in terms of quantities other than profit, such as cost savings. It can even be things that cannot be measured, known as soft returns. These can include time savings or productivity increases.

Other metrics related to automation investments

Several other key metrics can help you keep track of the AI performance, such as:

- Cash Flow

- Productivity

- Quality

- Accuracy

- Consistency

- Reliability

- Employee Satisfaction

Automation tracking best practices

Experts suggest following the data and continuously reviewing the Key Performance Indicators (KPIs) to ensure visibility from the factory floor up to the C-suite.

- Include a long-term plan when evaluating which process is best for your company.

- Remember that ROI may take a few years, but an extended view of this investment may lead to greater savings.

- Understand what the flexibility of your investment is after 3 or 5 years of implementation.

To properly define the performance metrics to track, you must first identify relevant KPIs for each business purpose where automation is being implemented.

Determining revenue generated by comparing a manual setup, semi-automated, and fully automated is also critical. Comparing these metrics will guide you to the right setup for your business.

Factors to include in your cash flow calculations can be:

- Labor savings

- Human training

- Implementation of an automation system

- Human resources

- Health care

- Retirement

- Quality control

- Depreciation

- Electricity

- Interest cost

- Maintenance

- Cost to scale

How to pick the right metrics?

The metrics you choose should be relevant to what your business already measures. Of course, certain metrics can vastly outweigh others. For example, if productivity is a more important metric to your business, give higher weightage to it.

Similarly, if you have less access to a labor market, automation becomes particularly important, and you need to give higher weightage to that. Each hire needs to add value to the business above repetitive tasks that are capable of being automated.

It might take you three or even five years to break even with the automation investment. However, as long as you evaluate the correct values, you will stay on top of automation performance and optimization.

To read more about the Buyer’s Journey:

Orchestrating Workflows Within Your Distribution Center

Justifying Robotics In Your Operations

Robotics – The Buyer’s Journey, Part II

To learn more about The Robotics Group (TRG): https://www.mhi.org/robotics