Powering Tomorrow’s Mobile Automation

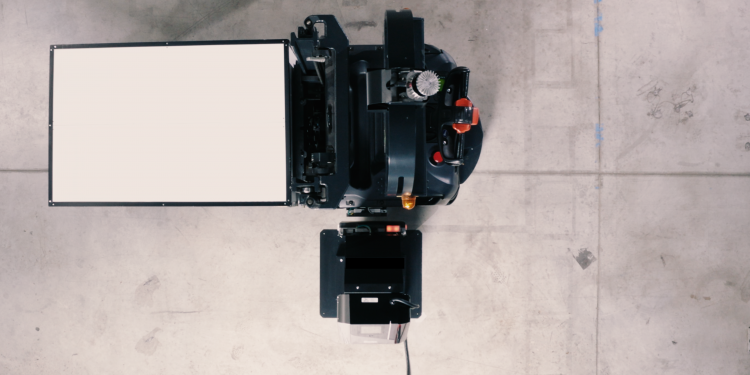

Adoption of mobile automation vehicles (MAVs) in warehouses continues to expand, especially as technology continues to mature—it’s been deployed in warehouses for several years now. Mobile automation is constantly proving its value, picking up repetitive, low-value tasks – freeing human employees to engage in activities requiring conscious thought and judgement skills. Based on need, MAV units come in a variety of models and configurations that enable operations to deploy them based on tasks and facility requirements.

But no matter the task, MAVs need a power source that maximizes working uptime. Traditionally, powering MAVs was similar to other material handling equipment, dominated by flooded lead-acid batteries. While flooded lead-acid managed to provide a certain amount of power, it has its challenges with MAVs. The biggest being it still requires significant human interaction.

Maintaining the flooded lead-acid batteries required for MAV throughput levels usually involves changing them out for recharging and watering, often in a dedicated area. Employees are needed for these tasks – taking them away from activities on the floor. If your operations are running in full swing, downtime for swapping out MAV batteries and dedicated employees for watering and charging them undercuts the core value MAVs offer.

But much of this operational loss is now mitigated by newer maintenance-free battery technologies like thin plate pure lead (TPPL) and lithium-ion batteries, both of which are designed to eliminate watering and change-outs. These technologies are engineered for “opportunity charging” – brief power top-ups during breaks, between MAV runs or other facility work stoppages.

Like battery technology, charging technology options are evolving as well. As operations glean increased efficiency and value for their MAV investment, current options like “hot shoes,” manual plug-ins or battery changing are becoming obsolete for MAV applications due to their personnel and maintenance requirements.

Similar to mobile consumer electronics, charging technology has now evolved to go wireless – eliminating routine human interaction. These wireless charging systems involve hardware and software to transmit power and communicate with the MAV battery for safety and charging efficiency, with a control system, charging station and charging pad on the MAV to receive the power from the charger. Since wireless chargers have no moving parts or physical connections, they also eliminate the need for routine lubrication and replacement of “wear parts.”

Wireless charging is about a year old and quickly gaining interest due to its ability to further free-up personnel. When working with an experienced partner, wireless charging enables MAV OEMs to differentiate their MAV systems and helps customers further shorten the ROI period on their automation investment. As MAVs continue to evolve, so will the power systems that support them – providing yet another step towards fulfilling the promise of full automation.

To find out more about MHI’s MAG Industry Group: https://www.mhi.org/mag

To learn more about how mobile automation can benefit you:

The Unexpected (Soft) Benefits Of Mobile Automation

Navigating The Mobile Automation Landscape

Getting Started With Mobile Automation

The Unexpected (Soft) Benefits Of Mobile Automation

How To Make Mobile Automation Affordable

Understanding The Differences Between AGVs And AMRs

Discover How Mobile Automated Vehicles Enhance A Variety Of Material …

How Mobile Autonomous Vehicles Address E-Commerce, Automotive And Food/Beverage Handling …