What to Expect from a WMS

Warehouse management systems (WMS) are nothing new to industry, but confusion still surrounds their features and benefits. There’s also a general lack of understanding about how a WMS differs from a warehousing module that is part of an enterprise resource planning (ERP) system. To get the most of your software investment, it’s important to clear up the confusion.

One of the biggest differences between a WMS and an ERP module is that a WMS will drill down much deeper on all the important operations in a warehouse. It can help you:

- improve inventory accuracy and control

- improve order fulfilment and accuracy

- help you avoid excess manual handling of goods and unnecessary steps

- get your products out the door quickly, with fewer costly errors

An ERP system, on the other hand, is more focused on financials, order entry, and scheduling production. Its warehousing module (WM) is less robust than a WMS; while the WM module may offer a decent starting point, it often falls short in addressing warehouse management features and functions that most organizations require. The modules might be slower than what a modern warehouse needs and will struggle with the demands of many operations.

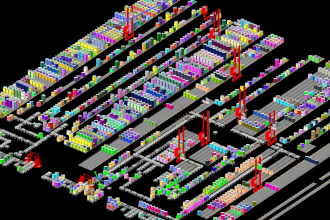

Investing in a WMS is truly an investment which provides an ROI and allows your organization to grow. You’ll get software that can set up order profiles and offer multiple picking methods to optimize order fulfillment. Likewise, the WMS may look at size, type, and date sensitivity (FIFO, FEFO, etc.), to manage customer demands in a timely fashion. It will use a variety of criteria to determine when you should pick what, and ensure it goes out to the right carrier at the right time in the fewest number of cartons/shipments…all a benefit to your customer, leading to an improved purchase experience and loyalty.

Drilling down more on the picking functionality you can expect from a WMS, the software can help you manage picking in a variety of manners, depending on what it determines is the best approach. This might look like ‘pick and pass’ operations, parallel picking, wave or waveless picking, zone picking, or any combination thereof. A WMS can also help with slotting. Over the course of a given year, you may experience seasonal peaks or fluctuations in customer demand. Based on increasing item and order velocity, some WMS will dynamically re-slot items to shift fast movers closer to pack/ship stations to improve throughput. As demand slows for these items, a WMS can direct faster moving SKUs to primary pick locations. They can be moved out of prime positions to ensure your warehouse accommodates the shifting order line-up.

More comprehensive WMS platforms will include Warehouse Execution System (WES) and Warehouse Control System (WCS) functionality that enable greater optimization and warehouse automation. WES functionality can provide the orchestration of actions inside a warehouse to help optimize its throughput. WCS control automated devices and equipment and as more warehouse operations incorporate automation into their processes, the benefit of controlling them with a single platform increases. A comprehensive WMS that includes WES and WCS can provide a very scalable solution for many businesses.

For more information about the Solutions Community: https://www.mhi.org/solutions-community

For further articles from the Solutions Community:

Cloud Vs On-Premises WMS: Which One Fits Your Business Needs?

Taking An Executive Overview Of WMS

The Digitization Of Intralogistics: Sortation

Creating A Flexible Order Fulfillment Operation

The Digitization Of Intralogistics: Storage