Robotics in the Warehouse

The collaborative role of robots and humans leads to big results. The term “robots” gets thrown around loosely, especially in the context of material handling. While it represents a very broad category of equipment, it can be helpful to understand ...

Using Simulation and Digital Twins to Increase Productivity and Quality ...

If you’re buying a car, you’re going to want to test drive it to see if you like how it handles, looks, and performs. You probably try out several different models, in fact, before signing a sales contract. In the ...

Advanced Energy Solutions Deliver ROI

Exploring how battery management systems provide rapid payback. Industrial trucks mainly use lead-acid batteries, but lithium-ion (li-ion) batteries are increasingly finding their way into warehouses and manufacturing facilities. One of the perceived barriers of entry, however, is the upfront cost ...

Digitization of Intralogistics: Software

There are multiple types of software solutions designed to optimize your warehouse. Here’s what each can and can’t do: If you take a scan of your facility, you’ll spot storage racks, conveyors, lift trucks, and maybe even mobile robots. They ...

Order Orchestration Optimization Through Robots

Today’s robots are more sophisticated than ever, as is the software that coordinates them. Orchestrating work flows to ensure efficient order processing is a complex job, even more so when completing interdependent tasks manually. Human capital affords vulnerability with potential ...

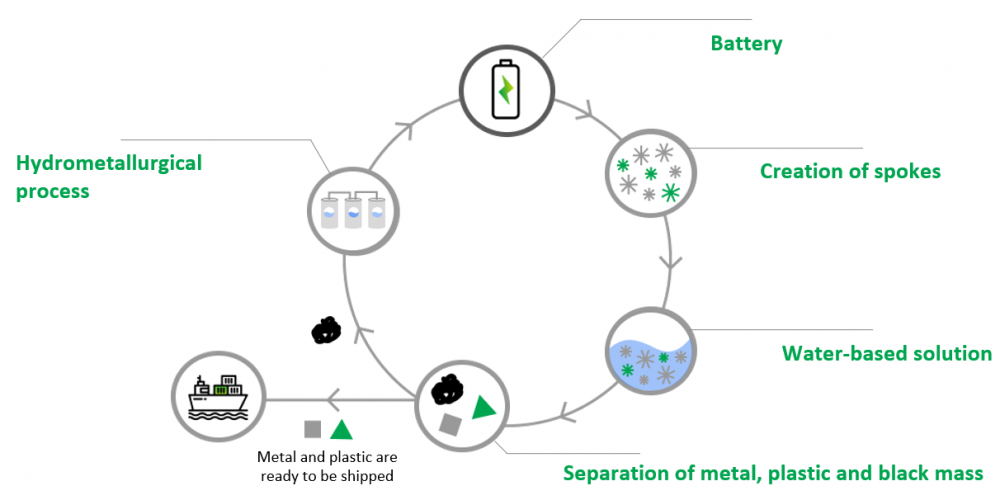

Achieving ROI with Advanced Power Sources

Sustainability gains can help you achieve an ROI with advanced power sources. One of the common misconceptions when it comes to investing in advanced power sources like lithium-ion (li-ion) batteries is that achieving a return on investment (ROI) can be ...

Optimize the Final 100 Feet

Efficient SLAM operations depend on software integration. Your shipping, labeling, applying, and manifesting (SLAM) area is a critical component to your overall operations. Known as the final 100 feet, SLAM is the final stop before your orders make their way ...

Using Peak Season for Next Season

Taking stock of your operations after peak season can set you up for future success. For most companies, peak season is just around the corner, and that means you are ramping up according to plans you carefully laid out. From ...

Maintenance Check: From Reactive to Predictive

Modern tools are changing the way you maintain your equipment—with big savings to be had. The normal, long-standing tradition with material handling equipment is to react when something fails. Your conveyor grinds to a halt and you bring in your ...