Although there have been concerns over the years that robots will ultimately replace humans — and take their jobs — in manufacturing, distribution and order fulfillment, their availability during the shutdowns associated with COVID-19 has helped numerous facilities maintain productivity. In industries ranging from automotive, to pharmaceuticals, food and beverages, and consumer goods, robots are helping to minimize the impact of workforce reductions and social distancing restrictions while keeping employees safe.

According to a recent article in MHI Solutions magazine, operations are taking advantage of the inherent flexibility of robots and deploying (or, in some cases, modifying and redeploying) them in numerous ways across supply chains. Three of the most common use cases include:

- Retooling for manufacturing. Operations have made adjustments to robotic end effectors and programming to support process adaptations to make personal protective equipment (PPE), test kits, and other medical supplies.

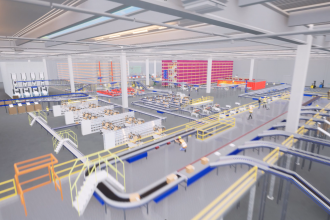

- Load and item transfers and transport. In manufacturing facilities — as well as in warehouses and order fulfillment centers — robots are traveling from one socially distanced worker to the next to deliver or pick up needed items for assembly, or to complete picks for e-commerce purchases. This minimizes human-to-human contact.

- Automated disinfection. Some operations have deployed robots that either spray chemical disinfectants or shine ultraviolet (UV) light on surfaces to deep clean workstations and other high-touch areas within facilities, protecting personnel from exposure to both germs and sanitizers. Similarly, drones have been equipped with crop-dusting equipment to spray disinfectant in locked-down cities in India, while germ-zapping robots have been increasingly deployed in hospital settings.

Want to learn more about how robots are easing supply chain challenges associated with the global COVID-19 pandemic? Read the full article, here.