How ASRS is Changing the Industry for Better

From big, tangible benefits to smaller, less tangible benefits, ASRS can change your operations game.

The pressures of operating modern warehouses are real. From the need to increase efficiencies, to labor shortages, space constraints, and more, everyone in the business is looking for equipment and strategies to help meet or beat those pressures. One of the best ways to accomplish that goal is by adding an automated storage and retrieval system (ASRS).

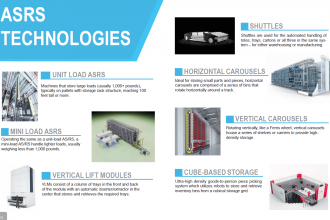

An ASRS is an automated, high density storage unit controlled by a computer system. Put simply, an ASRS automatically places items in storage and then retrieves them when needed. But the benefits are numerous, and all can lead to improved warehousing operations.

If you look at the numbers, when adding an ASRS to your operations you can hope to improve your productivity between 60 percent and 100 percent on average. Most of those gains come through a faster picking cycle—often between 40 percent and 70 percent faster than your manual approach. In some cases, automated picking and retrieval can increase productivity up to 300 percent.

Customers often turn to ASRS when their business ramps up, requiring them to manage a higher throughput and more cycles. Usually, they want to accomplish this in an existing footprint, with no additions or new builds required. That’s where ASRS can shine. By packing in more density into the existing footprint, ASRS allows companies to store up to 10 times the locations that standard racking can offer. When you move your items into an ASRS, you free up a good deal of floor space for other activities, thus improving your potential for higher productivity.

There are other ways that ASRS can change and improve your operations. These include smaller, less obvious benefits. While these might not be your motivating factors for purchasing an ASRS, they serve as icing on the cake and allow you to make the most of your new automation.

One less noticeable benefit that ASRS delivers is lowered product damage. For one, you’re taking the human factor out of the equation, thus avoiding human-caused mistakes that lead to damage. You are also now working with a system that is designed specifically to the types of loads you need to handle. These two details combine to reduce product damage, which is more critical than ever today in an ecommerce, high customer expectation environment. That can save you a good deal in fines or returned goods.

Labor is another less obvious savings from ASRS. While ASRS doesn’t replace your team members, it frees them up for more meaningful tasks. This can lead to higher retention rates and a good recruitment tool, saving you money. Some of that labor can even be dedicated to keeping the ASRS unit running.

You’ll also find lower CO2 and electrical consumption with an ASRS. On average, an ASRS uses 25 percent to 35 percent less energy than other technologies in the warehouse, leading to significant savings.

Finally, ASRS is not just about the physical movement of goods. It’s also about integrating high-end software into your system that can transform how you accomplish your storage and retrieval tasks. The software learns while you perform daily routines and can be a big game changer.

ASRS can be a valuable change agent in a warehouse, leading to substantial improvements.

For more information about the AS/RS group: mhi.org/as-rs

For further articles from the Automated Storage/Retrieval Systems (AS/RS):

Act Now to Beat Seasonal Order Picking Peaks: Your Complete Guide to Warehouse Success

Adding Robots to the Cold Chain

March 4 MHI Tech Talk Explores Integrating Racks With Automation

Is a VLM Right for Your Operations?

Understanding ASRS Software Integration

ASRS Is Perfect For Social Distancing

Podcast: How Does An ASRS Solution Differ And Complement AMRs/AGVs?