Logistics and the Importance of Digital Inventory

There are often many different areas of the supply chain that you can consider when referring to the digitization of logistics. It may be within your distribution center or extend out into your wider supply chain, including transportation. It all depends on the scope of your business and operations. When it comes to digital inventory, the scope starts within the four walls of your distribution center or manufacturing facility, but includes your other facilities, such as 3PLs and partner locations.

Let’s dig a little deeper and understand the importance of digital inventory and how it impacts the entire supply chain logistics.

What is Digital Inventory?

Digital inventory allows you to know exactly where your inventory is within each facility and your supply chain.

Think of it this way — there are myriad SKUs all over your warehouse and any of them can be at any step in the overall process. It can be difficult to stay on top of their location and prior to digital tools, the tracking and error rates could run high. Additionally, each SKU has unique attributes such as dimension, weight and packaging type (e.g., cuboidal carton or irregular shaped items like items packed in poly bag). Capturing the “master data” from each item with a dimensioning system designed for this can provide added benefits such as the ability to optimize storage and loading processes. Having a system to track your SKUs reduces the odds for mistakes and/or lost items, increasing efficiency and productivity — even after inventory has left the building.

How Does Digital Inventory Work?

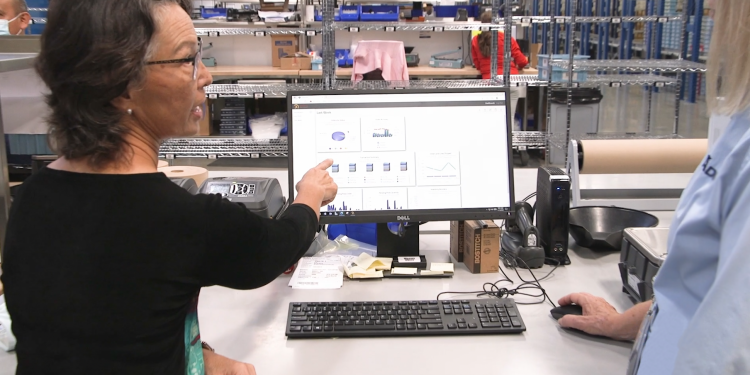

To carry out the digitization of inventory, items often arrive at the warehouse already barcoded. Then using scanner technologies that range from handheld to wrist-mounted and voice activated, employee’s intake the inventory, which is often automatically uploaded to a warehouse management system (WMS). Here’s where the tracking begins — the WMS serves as command central, recording when an item arrives and then following it as it moves throughout the facility.

Inventory then moves throughout the distribution center in a variety of ways. It could be on a conveyor or an automated robot like an autonomous mobile robot (AMR) might take the items away. Automated storage and retrieval system (AS/RS) such as vertical lift modules and shuttle systems can further enhance digital inventory. The WMS knows where the inventory is headed and ultimately lands. Warehouse associates can pull the items from shelves, prepare them for shipping and then send them on for their final steps. Again, a WMS can digitize and track these physical processes and when supplied with warehouse control system (WCS) or warehouse execution system (WES) functionality can manage and optimize labor and numerous automated systems.

Benefits of Digital Inventory

One of the best advantages of digital inventory is that it enables you to analyze your operations. You can look at myriad metrics, including how fast your pickers are operating; how much throughput you are achieving; where are your bottlenecks; where do you need to increase training; how quickly does your receiving department accomplish its tasks? And many more.

Armed with this digital inventory information, you can drill down and look at ways to make improvements, beginning with identifying the root cause of slowdowns and inefficiencies. This data can provide a roadmap for understanding why you might be accurate in one area of your floor and not in another. From here, you can establish new performance goals, compare facilities within your network and even benchmark with other industry distribution centers.

Your WMS will enhance these analyses and your WCS and WES will complement it, allowing for optimization of movement. When you’ve put it all together, you will have a strong foundation and be in a good place to continuously improve moving forward.

Further Blogs in Digitization Series:

Digitization Of Intralogistics

Intralogistics: Warehouse Digitalization Of Receiving

Simulation And Emulation In Risk Management

Click to find out more about MHI’s Solution Community