5 Major Reasons Companies are Automating Their SLAM Lines

The justification for automating SLAM is usually there, even for small- and mid-sized companies.

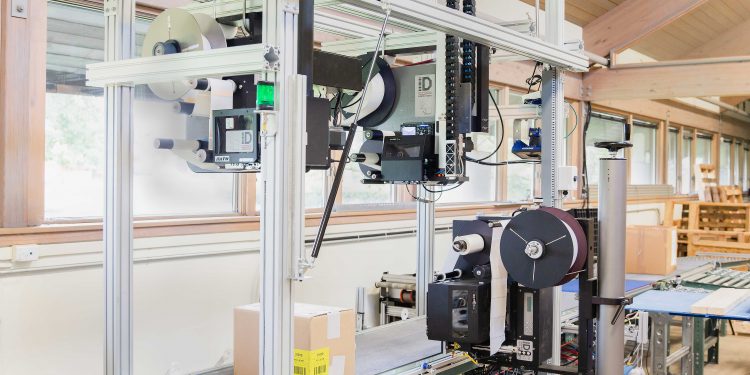

Automation seemed to be everywhere in the past year, and for many small- and medium-sized companies, justifying it can feel out of reach. But when it comes to automating your SLAM lines (scan, label, apply manifest), you might be surprised at . The final 100 feet of your operations are one of the best places to consider when looking to begin an automation journey.

To begin, you must consider your wants versus your needs, however, it’s easy to look to the bigger companies in your network, see their automation, and believe you need the same types of automation for success. But you need to take a step back with and determine how automated SLAM equipment can fit into your overall picture. Having a good trusted automation partner is also important. For smaller and medium-sized companies, the task of determining how to automate themselves can be daunting. That’s why we exist. To guide the customers in that process and help them understand what’s out there and how they can implement it.

Here are five major factors to consider before investing in your SLAM line:

Increased volume—If you’re experiencing more overall volume and struggling to keep up, automated SLAM might be helpful. Manual packing can be a drag on your speed, Automated SLAM equipment can weigh, dimension, label and manifest in a matter of seconds. This will not only increase the speed at which you manage your volume but cut down on the labor needed for the job.

High employee turnover—While warehouses can differ in size and verticals, many face the same struggles with the available labor pool. Finding steady, qualified employees is difficult with boomers retiring, stiff competition at nearby warehouses, and not enough younger employees entering the workforce. If this sounds like your facility, automated SLAM can be worthwhile.

High human error—Today’s warehousing requires a high level of regulatory and shipping compliance. This is especially true in the SLAM line. If your operations are struggling to meet those requirements and suffering a high number of chargebacks, you can likely offset those costs with automation. It works hand in hand with humans,

Mistakes in inventory tracking—If your operations are struggling to keep a handle on inventory tracking, SLAM automation may also be justified. This is another spot where removing some of the human elements can lead to big improvement.

Need to improve the bottom line—When you’re looking for steps that can help improve the bottom line, SLAM automation can be an easy way to make progress.

You don’t need to experience all these situations to justify an investment in SLAM, but they are each a good indicator that SLAM could make a difference to your operations. There is no one-size fits all approach. Each company will have different pain points—you should be aiming for the most impact with your automation investment. Here are some best practices when starting:

The good news about SLAM automation is that you don’t have to go all in right out of the gate. With several pieces of equipment, you can pick and choose where to invest and begin and then scale as needed after that.

For instance, you might find that a good starting place is These can be low-cost, low-risk places to begin with SLAM. Over a period of time, you may to your processes. In general, taking a slower, more scaled approach to SLAM automation is the path to success, rather than diving in headfirst with all the pieces of equipment.

Don’t forget that software integration will need to be a piece of your SLAM automation plan. Your WMS or ERP needs to be able to integrate with the automation and its associated software, too, for the best results.

You’ll also need to involve the right stakeholders in your company. While bringing all your systems together for a more automated approach can lead to substantial gains, it can’t happen without the appropriate buy-in and collaboration of all the necessary parties.

Finally, don’t do it alone. The right partner—whether an OEM or an integrator—is essential to your automation journey. Someone who understands the elements of SLAM, and understands your unique needs, will work with you to find the right starting place. From there, they will help you move forward at the right, scalable pace.

Automating your SLAM lines can have good payoff, but first, ensure all the right elements are in place.

To learn more about MHI’s SLAM industry group: www.mhi.org/slam

More information about Scanning, Labeling, Applying, Manifesting:

The Business Case for SLAM Automation

Maintaining Your SLAM Equipment

Change Management on the SLAM Line

Monitoring Sensors on the SLAM Line for Trouble

SLAM Solutions in the Pharmaceutical Industry

Order Personalization with SLAM